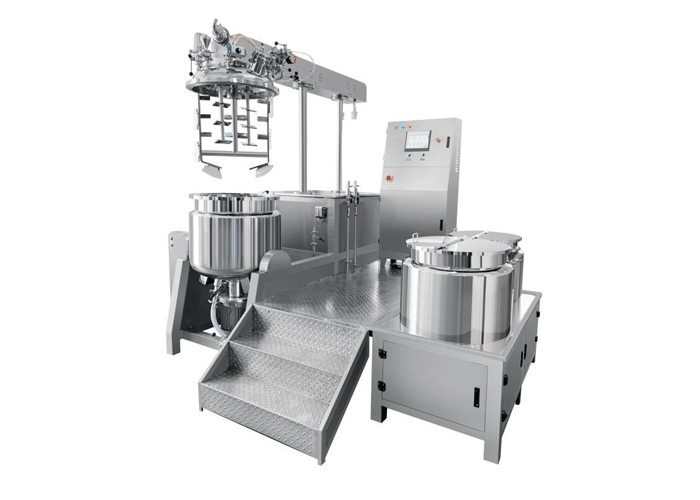

Choosing a new chemical mixer requires careful consideration to ensure it meets your specific needs. Various innovative mixer designs can enhance your process and provide a better mixing experience.

High Speed

Mixing is a critical step in the formulation process. It determines the final product’s texture, efficacy and compliance with regulations. Improper mixing can lead to craters, air voids in the finished product, soft or sticky surfaces, chemical or electrical resistance changes, oxidation and many other unwanted side effects. Look for high-speed chemical mixers to reduce the chances of these side effects. You also want to be able to adjust the speed easily. If you’re mixing in beakers, an easy-to-install clamping system is a must. Laboratory technicians may also have to lift the mixer’s head frequently during tests, so it needs to be ergonomically designed and easy to use. You can find mixers that offer electric lifting systems that make this task easier and safer. Mixers are integral to many industries, from manufacturing cosmetics and food to chemistry and aerospace. Choosing equipment that can meet the exact specifications of your products and production needs is critical. Fortunately, used industrial mixers provide the necessary flexibility without breaking the bank.

High Torque

Mixing and blending are vital steps for producing quality materials and products. If your materials have different processing times and agitation behaviors, consulting with a mixer manufacturer is an excellent option to determine the prop’s pumping rate for a specific model type and size at the RPMs it will operate. Stainless steel is the ideal tank material for chemical and pharmaceutical industries as it has high strength-to-weight capacity, corrosive resistance and easy cleaning. Choosing an inline homogenizer with a stainless steel rotor-stator high-shear mixer is ideal for mixing, dispersing, emulsifying and homogenizing two or more immiscible liquids. However, remember that a high horsepower motor does not necessarily mean the mixer will have more power. Selecting a high horsepower drive may lower efficiency, negatively impact your budget and damage the materials by too much shear.

Versatility

Many variables determine the most appropriate mixer for an operation regarding mixing and blending. Mixers not optimized for a given process can lead to costly agitation problems, including air bubbles, sticky surfaces, soft spots and dissolving or floating solids. Static inline mixers are also highly versatile and can be modified to suit various conditions. For example, a double-arm mixer can create homogenous mixtures that improve product quality and reduce wastage. This innovation is reshaping the industry and propelling companies into an era of enhanced manufacturing.

Safety

In the lab, mixing chemicals can be dangerous. The proper equipment and thorough cleaning are essential to ensure the safety of everyone handling a chemical. The mixer’s clamping system must be able to secure containers that vary in shape and size. Hinged access is necessary for cleaning, inspection or emptying. The ability to control the rotation speed of the blade is also helpful in determining mixing efficiency and results. Testing your materials at the manufacturer’s testing facility is also important. Using the mixer under mixer simulation will help you and the manufacturer determine how well the machine adapts to your products. This will prevent you from purchasing a mixer incompatible with your materials. It will also help you avoid mistakes when mixing your products with an industrial-grade mixer.